HOME >> products >> Welding Rotator >> Conventional

HOME >> products >> Welding Rotator >> Conventional

Quickly Details

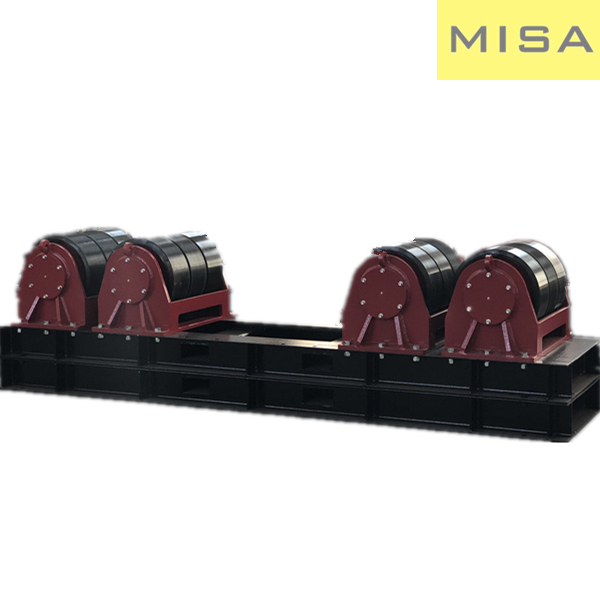

Type:Conventional Pipe-up Growing Line/Tank Fit up Rolls

Brand:MISA

Condition:100% brand new

Model number:HGK

Capacity:5Ton - 1000Ton

Consist: (1) Drive unit , (1) Idler unit , (1) Control box with hand panel

Voltage:110V-600V

Painting Color:Yellow & Blue /Yellow & Grey / Yellow & Black / Red&Black

Place of origin:Wuxi , China(Mainland)

Welding Rotator Product Photo:

Welding Rotator Product Parameter:

| Type | Max loading (kg) | Vessel diameter(mm) | Dia. and width of the wheel(mm) | Roller linear velocity(m/h) 6-60 | Power of motor(kw) | |

| Rubber rollers | Metal rollers | |||||

| HGKS-5 | 5,000 | Φ250-2300 | Φ250×100 | 2×Φ240×20 | 2X0.37 | |

| HGKS-10 | 10,000 | Φ320-2800 | Φ300×120 | 2×Φ290×25 | 2X0.55 | |

| HGKS-20 | 20,000 | Φ500-3500 | Φ350×120 | 2×Φ340×30 | 2X0.75 | |

| HGKS-40 | 40,000 | Φ600-4200 | Φ400×120 | 2×Φ390×40 | 2X1.5 | |

| HGKS-60 | 60,000 | Φ750-4800 | Φ450×120 | 2×Φ440×50 | 2X2.2 | |

| HGKS-80 | 80,000 | Φ850-5000 | Φ500×120 | 2×Φ490×60 | 2X3 | |

| HGKS-100 | 100,000 | Φ1000-5500 | Φ500×120 | 2×Φ490×80 | 2X3 | |

| HGK-S150 | 150,000 | Φ1000-6000 | / | Φ620×220 | 2X4 | |

| HGKS-250 | 250,000 | Φ1800-7500 | / | Φ660×260 | 2X5.5 | |

| HGKS-500 | 500,000 | Φ1800-8000 | / | Φ750×400 | 2X7.5 | |

Welding Rotator Detail Photo:

Welding Rotator Product Description:

Welding rotators are similar to positioners, in that it's a mechanical means to rotate cylindrical vessels. They minimise handling, increase efficiency, and dramatically improve the quality of workmanship from welders of all skill levels. MISA can supply conventional and self-aligning rotators to suit various sizes of weldments across a variety of sectors. Any steelworks with cylindrical vessels, be it small diameter piping to large industrial cylindrical vessels for windtower production, a rotator will be beneficial, sometimes a necessity. If the weldment is cylindrical, a rotator will make a huge difference to most welding processes including, SAW, TIG, MIG and ARC.

Welding Rotator Application:

1. Pressure vessels.

2. Pipe manufacturing industries

3. Wind power fabrication

4. Cylindrical tank's welding, polishing, rubber lining, assembling ,etc

5. Chemical & fuel storage tank fabrication

6. Any heavy cylindrical job

Welding Rotator Packing and Shipment:

Kindly Noted:

1. Model from 5T-100T, others please let us know.

2. One set of welding turning rolls include one drive & one idler, also customer can choose other combinations.

3. Voltage standard is 380V, 50HZ, 3PH. Other voltage please kindly let us know.

4. Control panel is wired control, or you can choose wireless control.

5. If need more special requirements ,we'll study with our engineer.

6.The revolve adopt A.C. Inverter motor driving.

Related Products:

Why always MISA?

360°guarantee makes ordering risk free.

20 years welding machine manufacture experiences.

one-stop service of welding.

OEM service.

Quickly feedback for your problems.